Elektrodispečink

Dopravní podnik města Olomouce

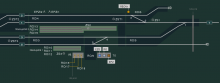

Řídicí a monitorovací systém měníren tramvajové dopravy, ovládání zařízení PTZ a vytápění výhybek. Redundantní systém s plně zálohovanou datovou komunikací WAN/GSM LTE. Řídicí systém QuickControl, PLC SAIA PCD3 a TECOMAT.